Solution for UV prevention

Currently, Polycarbonate sheet is widely used in the construction industry in countries around the world and in Vietnam. Polycarbonate sheet is used mostly in the following areas: roofing for stadium, sports club, roofing for light-absorb, greenhouse, dome yard, bus station and airport,.... Due to the direct impact of weather and sunlight, especially ultraviolet (UV) radiation, the main agent causes damages to the panel: blurring, reducing light transmission, yellowing and cracking. This is the aging phenomenon of Polycarbonate sheet that reduces the life of the product. In addition to harm to Polycarbonate sheet, UV rays also have an adverse effect on human health (causing skin cancer, etc.). To overcome this problem, VP Polycarbonate sheet of Viet Phuoc Plastic Joint Stock Company is manufactured by modern extrusion technology with the official materials of Bayer (Germany) famous in the world.

- Polycarbonate material with Makrolon 1243 code with multi-molecule branched chain structure, suitable for the production of hollow PC sheet, this material is added with anti-UV additives to increase the anti-aging.

In addition, with the advanced extrusion technology, the Polycarbonate sheet of Viet Phuoc Plastic Company is coated with a layer of Polycarbonate 1816 material with anti-ultraviolet of 40-50 μm thickness on the surface of panels impacted directly from sunlight, helping to increase longevity by reducing the aging ability of the product.

VP polycarbonate sheet is warranted for 10 years in weather conditions in Vietnam. Product life-cycle determination is based on the Bayer Company's Material Testing with Weather Simulator: Xenon tester (Xenon arc light). Testing time is 9,000 hours equivalent to 10 years and testing mode with Vietnamese climate condition.

* Testing results are as follows:

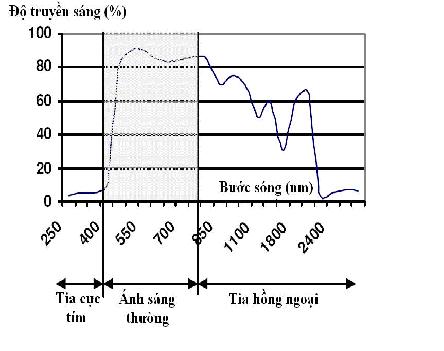

VP Polycarbonate sheet with a 50μm thickness anti-ultraviolet surface, preventing most of ultraviolet (250nm - 400nm wavelengths), with only about 4% of ultraviolet radiation penetrating through the panel. While most of light rays (400nm - 850nm wavelengths) pass through, the light transmission of the plate reaches 85-90%.

By preventing up to 96% of ultraviolet rays, it should increase the life of the product to 10 years while avoiding the negative effects of UV rays, contributing to the protection of public health.

The light transmission of the panels is negligible, reducing only about 2%.

The yellowing rate of the plate is not changed significantly, only decreased by 3%.

Engineer Nguyen Cao Phong

Technical Officer of Viet Phuoc Plastic JSC

MAIN OFFICE

Address: Lot K - 3 - Branch, My Phuoc 2 Industrial Zone, My Phuoc Ward, Ben Cat Town, Binh Duong Province.

Phone: 0274.355.3360 - 0919.893.360

Fax: 0274.355.6000

HANOI REPRESENTATIVE OFFICE

Address: 11th Floor, Zentower Building, 12 Khuat Duy Tien, Thanh Xuan Trung Ward, Thanh Xuan District, Hanoi

Phone: 0247.108.1868 - 0912.265.404

Fax: 0243.200.2609

HO CHI MINH CITY BRANCH

Address: 251 Pham Van Bach Street, Ward 15, Tan Binh District, Ho Chi Minh City

Tel: 0919.923.360